Sterilization Theory

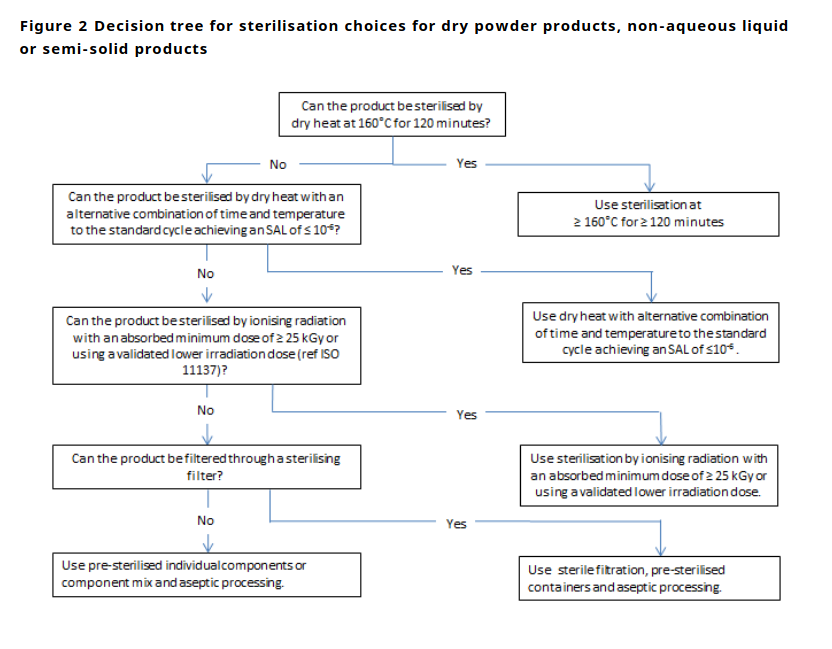

Sterilization requires a set of knowledge specifically catered to the compounded product that you’re working with. Sterilization is not so cut and dry that every solution works for everything.

Our CSP (compounded sterile preparation):

-

Is a non-aqueous liquid (it’s not water, it’s oil)

-

Starts with non-sterile components

-

Cannot endure dry heat sterilization (due to the benzyl alcohol1 and rubber stoppers2)

-

Cannot be sterilized by steam (it’s non-aqueous and due to the benzyl alcohol1)

- USP 797 says: “Steam sterilization is not an option… if there is insufficient moisture to sterilize the CSP within the final, sealed, container closure system”3.

-

Can be filtered

Filtration and Aseptic Technique

For the above reasons we are going to need to sterilize our compounded preparation using solely filtration and aseptic technique.

Why doesn’t dry heat sterilization work? (Ovens)

Dry heat sterilization generally involves heating something up to 160°C for at least 120 minutes. Any time there is no steam and pressure contact being made with the subject of the sterilization, it’s considered “dry heat.” A glass wall between the steam and the contents of a vial make it’s autoclaving still technically “dry heat,” as the steam does not make contact with the contents of the vial.

You cannot dry heat sterilize finished vials.

Reason 1: benzyl alcohol, the vital preservative in the vial, can break down, release a toxic byproduct, and evaporate with heat (more info)

Reason 2: butyl rubber stoppers begin to break down and off-gas (more info)

Reason 3: benzyl benzoate may break down with heat

Reason 4: while anecdotally the hormone may remain stable with high heat, there is no scientific evidence to support this.

Why doesn’t steam sterilization (autoclaving) work?

Reason 1: same as reason 1 above, benzyl alcohol can’t handle the heat. (more info)

Reason 2: for steam sterilization to be effective, the product that is meant to be sterilized must come into contact with steam, not the container or vial, but the product itself5,6,7.

Reason 2a: This isn’t true IF the contents of the vial are water based, that way the contents can create their own steam and pressure system as they heat up. However, our CSP is oil based, so this won’t work.

USP 797 says: “Steam sterilization is not an option… if there is insufficient moisture to sterilize the CSP within the final, sealed, container closure system”3.

”I think you’re wrong, it’s about the energy transferred to the glass vial by the steam”

No. It’s true that the energy transferred to the glass will happen more quickly in the steam than in dry heat, but that energy transfer still maxes out at 121C, far below what’s needed when there’s no steam/pressure making contact with the microbes. Without the steam making direct contact to the microbes in question, this is just heating something up really fast, the steam isn’t doing anything else.

Filtration & Aseptic Technique

Filtration and aseptic technique is the only viable combination that can get us safely sterilized vials. Be wary of anyone who is teaching how to homebrew HRT and does not understand these concepts fully and clearly. There is no benchmark that someone has to hit to be able to write about and teach this stuff online. There are lots of highly unqualified people out there giving bad advice. 99% of advice I find online about how to homebrew is incorrect.

References

Some sources pulled from HRT Cat

View the library page for access to some PDFs.

Footnotes

-

More research about benzyl alcohol here ↩ ↩2

-

More research about rubber stopper here ↩

-

Guideline on the sterilisation of the medicinal product, active substance, exicpient and primary container ↩

-

Compounding Sterile Preparations, pg 254 ↩

-

Steam Sterilization vs. Dry Heat Sterilization For Medical Devices & Products ↩

-

Steam Sterilization Principles & Common Mistakes Using Autoclaves ↩