How to Export This Site as PDF

This single page contains the full website listed in the same order as the sidebar. In your browser, simply attempt to print the page, then, instead of a printer select “Save to PDF.” Now you have the whole site available to you offline.

Note that the recipe calculator does not work on the PDF so be sure to get your recipe ahead of time.

404 - Page Not Found

This URL may have changed! Try using the search bar to find what you’re looking for.

How to Make DIY HRT for You or Your Community

Version 0.6 (Beta)

HRT Mom is a website dedicated to science-based, and lab tested methodology for homebrewing HRT. While there is much speculation as to how to best make HRT for injections at home, HRT Mom sticks just to the facts and avoids making assertions based on popular opinion or what feels most convenient.

Homebrew is hard. Consider buying from a community trusted vendor or making topicals before embarking on making your own injectables.

Please read the legal disclaimer before proceeding

I have spent over a thousand hours pouring over lab manuals, compounding manuals, USP guidelines, research papers, consulting with professional scientists, working in my home lab, injecting what I create, and writing reports on all the information I learn. All of this work is solely to bring you this guide. I’ve additionally invested thousands of dollars into equipment and experimentation to help work out the kinks in my lab. Up until recently brewing HRT at home has been a task of approximation. People share and publish guides and info on how compound HRT but they never fully understand what it is that they’re writing about. This website changes that. All information that is shared here is based on empirically validated research and its resulting logic. Any claim that cannot be backed up is flagged as an opinion of the author.

Start Here

| Sidebar Category | Explanation |

|---|---|

| How to Use This Website | An overview of how the site is structured and how it’s intended to be used. |

| Knowledge Base | Details all the ancillary knowledge that it’s good to have when brewing |

| Homebrew Guides | Details 3 different methodologies for how to make homebrew, depending on the volume you’re making |

| Homebrew Method Critiques | Analyzes various popular homebrew guides and provides science backed critiques on them including Lena’s and HRT Cafe’s |

| Blog Posts | Articles looking at specific topics related to homebrew that might not fit anywhere else |

| Library | Gathers the most important source material and makes it accessible for download or viewing |

| x | Any title with an “x” next to it indicates that I’m still working on the page. |

Dear Penelope

Have a question about something on the website? Have a question about your brew process? You are welcome to send your question, in letter format, to my email. Questions that cannot be answered in a short email response will be fully anonymized and published on the website with my response so everyone can benefit. Find my contact information here.

Export this Site

Our lovely developeromg that's me wow a shoutout 🥺❤️ has created a module to allow this entire site to export as a PDF. Find that here.

Find an Error?

Please email to let me know. Be sure to include your reasoning for why it’s an error and cite your sources if applicable. Contact.

Emails that are critical of this site’s methodology that are unable to back up their critique with mainstream published research will be ignored.

Donate

I am poor and I have devoted over a thousand hours and thousands of dollars to this project. Donations will go towards continuing research. Donate here. Contact me me first if you’d like to discuss how your donation will be used, we can absolutely work out a plan together.

Legal

Please do read the legal disclaimer. It’s short.

Vendors

this page is incomplete and possibly out of date

Vendors are not vetted. We do not know if these vendors follow the same brew methodology as taught on this website. We know that the online DIY community generally has good luck with these vendors. Their vials have not been submitted to mass spectrometer or sterility testing.

Homebrew Vendors:

0Closed or Not Recommended Vendors:

0Contact

My associate, HRT Dad, may reply.

Encryption

If you need to send us an encrypted message, please use proton mail in order to leverage the built in end-to-end encryption. If you’d prefer to use a different type of encryption, please send us an email and let us know.

Response Time

We check the email at most once a week. Please be patient for our response.

Legal

Legal notices on this page are based on US law but may pertain to other jurisdictions.

Testosterone

Please note that manufacture, possession (without prescription), or sale of testosterone is illegal in some jurisdictions, including the United States. This guide is intended to be used in full compliance with the law. Testosterone should only be imported, compounded, or sold in jurisdictions where it is legal to do so.

Estradiol

The manufacture, possession, or sale of estradiol may be illegal in the United States. Estradiol is not a controlled substance but it is still a regulated pharmaceutical. This guide is intended to be used in full compliance with the law. Estradiol should only be imported, compounded, or sold in jurisdictions where it is legal to do so.

Not for Medical Use

All compounded preparations made using this site are not considered for medical use, and should not be labeled as such. Labeling them as medicine would be inaccurate as they do not go through any regulatory process.

Do Not Suggest How to Use

As this is not medicine, and you are not a doctor or a pharmacist, it would be inappropriate and potentially unlawful to suggest to people how they should use it.

Not at Fault

HRT Mom cannot be held responsible for how the information on this website is used. Proceed with caution.

Donate

HRT Mom performs experiments and research in an effort to improve the processes documented on this website. All results of experiments will be shared freely with the public.

Monero (preferred)

88Xq69Hj2ax2L3qJCEnHv5iRCDSADq1Uxafy2n1RkHJhFQrNqW7VEfjHuT1zdSPNe1PrNwkzzdZTyLyEmybp89whBq982zYBitcoin

bc1qrtqsfsjkcujtjcpychtrg9f6cmxvznjy3g0eztNeeds

- Full sterility testing setup ($2,000+)

- API reagent testing setup ($unknown, pending research)

- How much benzyl benzoate is needed to stay in solution? (Anon reports crashes that are invisible at low BB vol. but hurt to inject)

- Various homebrew methods vs. sterility testing

- Breaks from work in order to focus on project

HRT Mom Backup

This site is hosted at https://hrt.mom (Swedish Server, subject to change)

There is a backup of this site at a slower server at https://scienceclass.pages.gay (UK and Netherlands Servers, subject to change)

I recommend using the hrt.mom domain unless there’s a problem, then use the backup.

The two sites should always be in sync with identical content unless we’re experiencing server issues.

How to Use This Website

Determine which guide you’re following

- The personal size guide is to help you make one or two vials for you and maybe a very close friend.

- The medium size guide is for around 20 or so vials. I find this methodology absolutely maxes out at around 60 vials without some teks.

- The large size guide is to help you make many, many vials. This methodology maxes out at around 200 vials because you’re a human, not a machine.

Read about sterilization theory

This page describes how sterilization works in the guides I write, and can also help you understand why other guides fail to properly sterilize. I’d label this as required reading, especially if you’ve brewed before with other methodology.

Read your guide in full

You need to have an understanding of your guide as a whole unit. You by no means need to memorize it, but you should be able to see the full picture of what the guide is instructing you to do before you do it.

Build your knowledge

As you’re getting all your supplies and materials in order, spend some time reading through the side bar, especially the knowledge base section. You don’t need to ready every single thing in full, but you should familiarize yourself with what information is available on this website. If a question comes up in the brew process, you should be relatively confident that you can get on this website and answer the question for yourself.

People who do this work professionally don’t just come off the street and start working. They have a very serious amount of study and training that they have to do before they’re allowed anywhere near stuff like HRT, which is considered a “high risk” preparation, and of the most difficult to compound correctly (even in a proper lab setting). Don’t discard how the professionals work, consider them role models for how we should approach our home lab projects.

If you want to do this correctly, especially for the medium and very especially for the large guides, you’re going to need to work very hard, study hard, and strengthen your mindset. Brewing in volume is not a weekend project.

Build your Mindset

Very Important Step!

What you’re trying to do, compound HRT at home, is not a fully understood task. Actual step-by-step guides from state of the art pharmaceutical labs have not leaked to the public, and even if they had we wouldn’t have the equipment to replicate them. So not only is this difficult to do correctly, but we don’t have a 100% understanding of what “correct” even is.

Your mindset, then, becomes your most invaluable ally.

You should always be asking questions, striving to understand better. If you disagree with me, or you disagree with someone else giving advice, can you find hard data backing what is true? And can you think critically enough to determine if the data is actually relevant or not? Always dig deeper, always expand your knowledge, always ask questions. Never assume you know anything for certain.

If you’ve brewed before…

It’s worth comparing all the differences between what you did last time and what you’ll do this time. Building up an understanding for why things are done one way, and not another, can help you to perform better when you’re working in your home lab.

Check out the Homebrew Methods Critiques menu in the sidebar to see if you’ve used any of the guides listed there in the past.

Familiarize yourself with the available teks

Tek: a technique for completing a DIY, science based task. A popular term in the home mycology community.

Also in the sidebar are some teks that can make your life way easier. They’re designed to plug into the guides that you’re following (medium and large only).

Autoclave Sterilization

Better than Using an Instant Pot

A true autoclave has substantial advantages over using an instant pot:

- Gets up to proper temperature

- Gets up to proper pressure

- Needs to operate for less time

- More reliable

- Able to use sterilization strips to verify if temp/pressure achieved

- Better data to support use

- Substantially better water control, resulting in sterilized items that are less wet

How to Operate an Autoclave

Your autoclave needs to be operated according to the manufacturers instructions. There’s no universal way to do this.

All items need to be washed in alconox and triple rinsed in distilled water before being loosely packed into autoclave pouches.

Inside the autoclave you can loosely drape a towel over the items in pouches. This towel will collect water that drips from the lid of the autoclave and will prevent that water from getting into the pouches.

Sterilization Parameters1

- Temperature: 121°C

- Pressure: 15 psi

- Time: 20-60 minutes*

*You’re supposed to choose a time that you can verify is correctly sterilizing your product. Since that’s typically out of scope for DIY operations, you may choose to sterilize for the maximum recommended time. The CDC recommends 30 minutes2.

Dealing with Wet Pack

After removing the items from the autoclave inspect them for “wet pack.” Wet pack is when water gets into your autoclave pouches. This is bad. Water that is left in a pouch, undealt with, can promote the growth of bacteria. Expensive, lab autoclaves have features that prevent or reverse wet pack automatically. To deal with wet pack you can transfer the pouches to a foil lined baking dish, that you then cover with another layer of foil. Put this dish in the oven at a very low temperature, such as 170F, you can even leave the oven door slightly open to promote a lower heat. Check on the wet pack every 5-10 minutes until you’re confident that all the water has been evaporated.

References

View the library page for access to some PDFs.

Footnotes

-

USP 797 section 10.3, 2024 edition ↩

Benzyl Alcohol

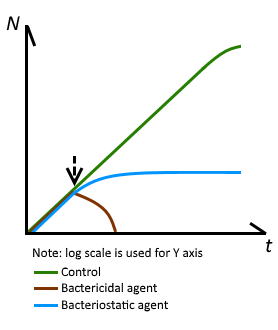

Benzyl alcohol is bacteriostatic and is used as an antimicrobial preservative against Gram-positive bacteria, molds, fungi, and yeasts, although it possesses only modest bactericidal properties1

Benzyl Alcohol (BA) is a required ingredient in all homebrews.

Benzyl Alcohol can break down2 and evaporate3 with heat. Never heat BA, even in a sealed vial.

BA is a bacteriostatic preservative that stops bacteria from multiplying, but does not kill bacteria.

NEVER increase the concentration of BA for ANY reason. Follow a proven recipe closely, one that likely recommends 2% BA. Injecting BA in higher concentrations than what is typically in a vial of HRT, 2%, is potentially dangerous.

Concentrations less than 2% could allow bacteria to proliferate.

Don’t heat it!

Benzyl alcohol is frequently used as an antimicrobial preservative or co-solvent in a varity of pharmaceutical injection formulations. The main toxic oxidation product, benzaldehyde, arises from the oxidation of benzyl alcohol upon long-term storage or heat sterilization of parenteral dosage forms containing benzyl alcohol, if oxygen is not excluded totally by nitrogen flashing. The presence of this potential impurity needs to be monitored owing to its reactivity and toxicity2

This paragraph is in line with the compounding industry’s steady stance that anything containing benzyl alcohol needs to be sterilized using filtration + aseptic technique, and not heat.

Further, benzyl alcohol has a flash point of just 101°C (214°F)3. This means that if you are to ignore the above advice, and you try to sterilize BA through heat, that a significant portion of it is being evaporated. This causes a problem because 1) we don’t want the BA to evaporate, we want it to stay in solution, and 2) if it’s evaporating out of an open container, this is a major flammability hazard.

10.1 Reactivity

Forms explosive mixtures with air on intense heating.

A range from approx. 15 Kelvin below the flash point is to be rated as critical.3

15 Kelvin below the flash point (101°C/214°F) is ~87°C/189°F — this is far below autoclaving temperature (121°C) or dry heat sterilization temperature (160°C).

10.4 Conditions to avoid

…

Strong heating.3

Benzyl alcohol oxidizes slowly in air to benzaldehyde and benzoic acid; it does not react with water… some solutions may generate benzaldehyde during autoclaving.1

So let’s not autoclave it or dry heat sterilize it? Rule #1 of homebrew: Don’t fuck with your benzyl alcohol.

Careful around plastic and rubber

Problems may occur when polystyrene syringes are used with certain types of drug products containing benzyl alcohol since these agents can extract and dissolve the plastic. At times the rubber tip may release a constituent to the drug product.4

Benzyl alcohol can damage polystyrene syringes by extracting some soluble components.1

According to wikipedia, most medical syringes are made of “polyethylene.” I’ve also seen a lot of syringes made of polypropylene on Google. So thinking these polystyrene syringes might not be too common. Regardless, the issues with the rubber tip are universal to the type of plastic in use.

It may, then, be best to measure the BA for your brew using a glass graduated beaker or cylinder so that the 100% BA doesn’t make contact with the rubber. Or, if your BA is in a sterile 100mL vial, to draw from it in a way that minimizes contact with the rubber in the syringe.

Neutralize it for Sterility Assurance Testing

Antimicrobial activity is reduced in the presence of nonionic surfactants, such as polysorbate 801.

If you’re performing sterility assurance testing, BA will interfere as it prevents bacteria from growing. You can use polysorbate 80 to neutralize it. It’s unclear how much is appropriate to use, pending further research.

References

View the library page for access to some PDFs.

Footnotes

Benzyl Benzoate

Benzyl Benzoate (BB) is a solvent found in most homebrew and pharmecutical vials.

Tyger’s guide says:

Lower concentrations of BB are generally desired to decrease the amount of post-injection pain that some people experience. However, there are so many different combinations of hormone ester, hormone concentration and carrier oil that it’s diffcult to know how low you can go. Low solubility will paradoxically cause more pain, even if the ester hasn’t visibly crashed.

Some homebrewers claim that you don’t need any BB at all, and I often get requests for custom vials without it, so consider stocking this as an option. I think a lot of people assume they are sensitive to BB without first trying another carrier oil or considering that their post-injection pain maybe caused by a dirty vial. Maybe I’m just reluctant to stop using BB, as it makes the oil thinner and therefore easier for me to work with.

Keep in mind that Tyger does not cite their sources, and that this information is word of mouth.

Don’t expose to heat

Exposure to excessive heat (above 40C) should be avoided.1

Unfortunately there is not more information available from this source on why we should avoid heat. However, your BB will be mixed with BA, which, we have better data for, and also should avoid heat.

References

View the library page for access to some PDFs.

Footnotes

-

Handbook of Pharmaceutical Excipients (2009), page 67 ↩

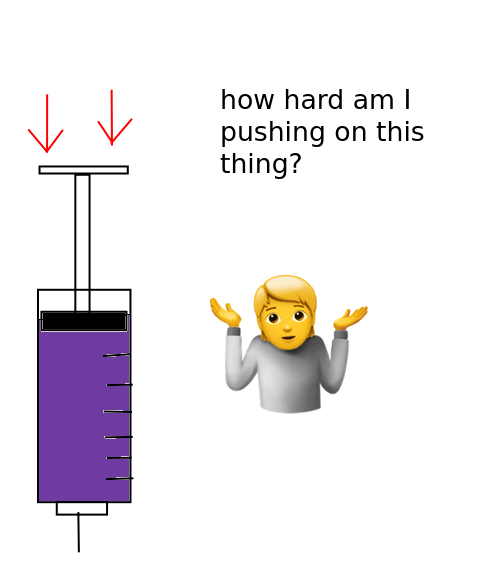

Bubble Point Testing

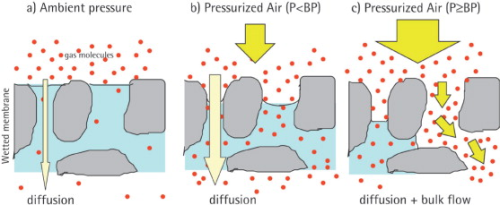

Syringe filters are how our compounded preparation achieves sterilization. Bubble point testing is how we verify that our filters maintained integrity during the filtration/sterilization process.

Especially in lieu of more formal sterility assurance testing, bubble point tests are our primary method for determining if our compounded preparations are indeed sterile.

A bubble point test will render your filter no longer sterile. Once you do the test, it’s important to discard the filter. Read more below.

Bubble point tests are standard in lab settings, however this particular methodology for doing them seems to have come from HRT Cat.

Diagram

Concept

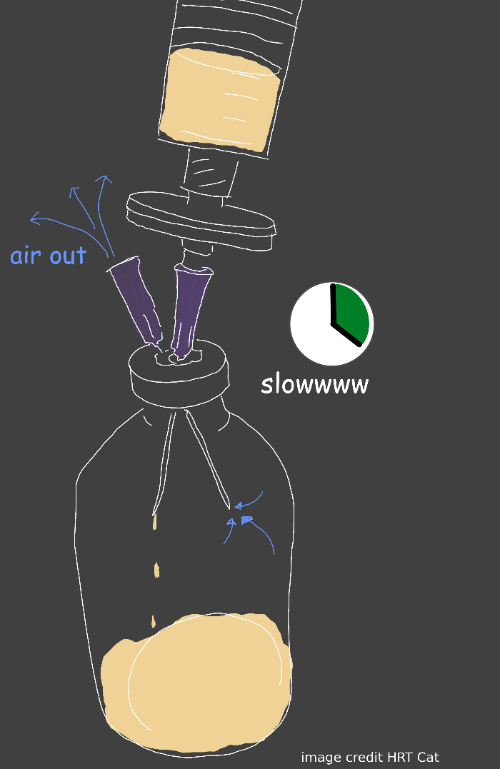

A syringe filter that is wetted with the preparation you’ve made will resist air being pushed through the membrane of the filter. However, once a significant enough amount of pressure of air is being pushed through the filter, eventually the filter will give way and let the air begin to pass.

So what we’re doing is checking at what specific pressure did the filter membrane begin to let air through. All filters of the same manufacturing batch, that are without defect, and are wetted with the same substance should begin to let air pass at roughly the same pressure.

We can use this info to check, then, if the filter broke or degraded during the filtration process.

We dip the end of a needle that comes out of this filter into a cup of water so that we can see when air begins to escape the filter.

Preparing a New Batch of Filters

From your new batch of filters, take as little as one, but as many as three filters. Pass a small amount of the compounded preparation through them, to the point where the liquid is going into the filter and is coming out the other side. This is considered “wetting” the filter, so that all of its pores are saturated in the compounded preparation.

Now that the filters are wetted, check their bubble point, taking the average of the three, and discarding any outliers.

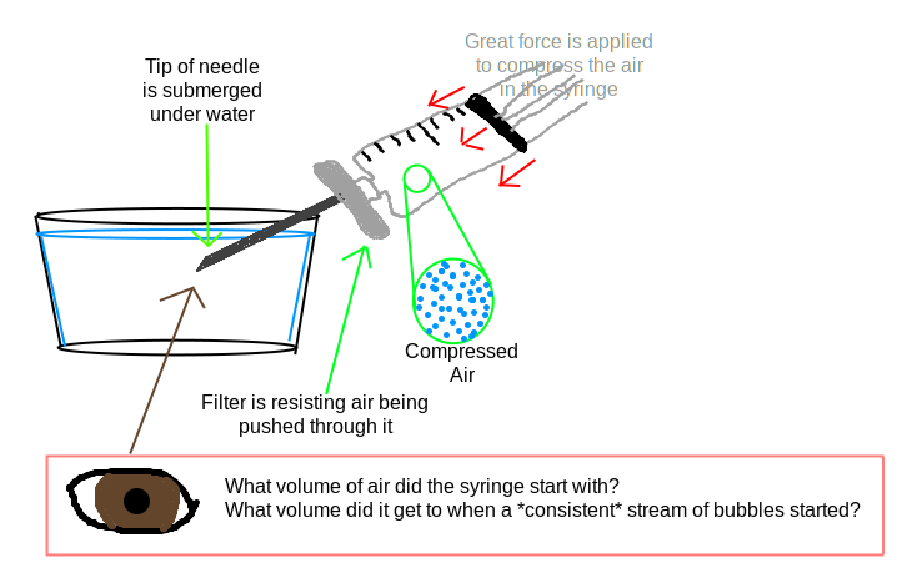

How to actually do the bubble point test

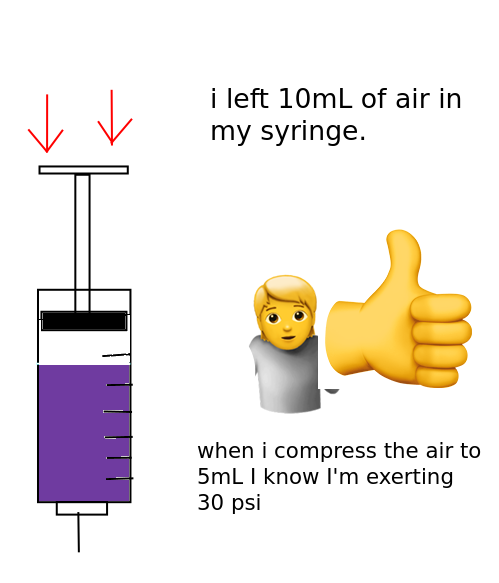

- Find the current air pressure. At sea level this averages at about 14.7psi. You can lookup the current air pressure where you’re at with a weather site.

- Take a large syringe, such as 20mL. Fill it up with air to a benchmark of your choice. I always fill up to 15mL of air, every time, for consistency

- Attach your used filter you want to test. (The filter must have had your preparation passed through it so that the pores are saturated).

- Attach a large gauge needle, such as 18g, to the end of the filter

- Submerge the needle in a glass of water, but not letting the filter touch the water.

- Compress the air in the syringe, trying to push the air through the filter and into the water

- Keep pressing down, remembering what mL you started at, and watching for a steady stream of bubbles to come out of the needle. A few bubbles is fine, and not relevant, you’re looking for a stream.

- Make note of what mL you were compressed to when the stream of bubbles started.

- You’re done.

Because I always start at 15mL of air, I know without doing math, that depending on my filter batch, my target bubble point of an in-tact filter is usually around 4mL (about 55psi).

Now you need to do a little bit of math to convert these values into a PSI bubble point. Open up the Boyle’s Law Calculator . Use today’s air pressure according to the weather as the starting pressure, use your starting volume in the syringe, and the volume where you saw the stream of bubbles appear. You should then be given a “final pressure” that tells you what the bubble point is.

You can now determine if your filter held up during its filtration. You should discard the filter and not use it again.

My bubble point is less than it’s supposed to be

Sometimes your bubble point turns out to be 45psi when it’s supposed to be 55psi, for example. Other times, you’ll see something more dramatic, and your bubble point will be 25psi when it’s supposed to be 55psi.

With the 25psi value, it’s safe to say that your filter broke in some way during filtration, and that the batch you filtered needs to be refiltered as it cannot be considered sterile.

When the deviation is smaller, that’s a tougher decision. I try to consider that my bubble point needs to be consistently at the benchmark I set for the batch of filters, in this example, that’s 55psi. So anything less and I consider that something might have gone wrong, I might have broken the filter somehow, or it was just a bad filter from the factory.

Someone less risk adverse than myself might consider that a small deviation is fine, and they want to consider the filtered preparation sterile. I have no data backing this up, and don’t know how to reliably tell what the cut-off is with bubble points. So my best advice is to stick to the bubble point you expect to get, and whether it’s a large or small deviation you should refilter if needed.

This test renders filters unsterile

With a large amount of pressure pushed up against the filter, and the needle leaving the filter being in unsterile water, if there is even the slightest decrease in pressure from your hand wavering or getting tired, while the needle is under water, you can notice that the needle will suck up a tiny bit of water.

This water is unsterile and impossible to get out of the exit side of the filter. Any sterile preparation that is passing through the filter now could be coming into contact with this water, effectively making the preparation unsterile.

References

View the library page for access to some PDFs.

Footnotes

Carrier Oils

Most above board compounding pharmacies use castor, sesame, cottonseed, or sunflower oil for making HRT.

Most DIY homebrewers are using medium chain triglyceride (MCT) oil. Sometimes called “Viscoleo,” MCT oil is more viscous and therefore may make the absorption rate quicker. It’s viscousness makes it easier to inject for the clients and easier to filter for the brewers.

MCT oil is a mix of C8 and C10 fatty acids. Your bottle of MCT should tell you the ratio of these two, I’ve found that most pharmaceutical grade MCT is a 60/40 blend of C8/C10. If you’d like to calculate the oil density you should know the blend ratio.

Some more info from an article on Transfeminine Science below:

It is in any case known from other studies that different oil vehicles are absorbed at different rates from the injection site and can result in different concentration–time curve shapes. This is thought to be due to differences in oil lipophilicity and depot release rates. Viscosity of oils has also been hypothesized to potentially influence rate of depot escape. However, research so far has not supported this hypothesis. Oil vehicles can vary with injectable estradiol preparations even for the same estradiol ester. For instance, pharmaceutical estradiol valerate is formulated in sesame oil , castor oil , or sunflower oil depending on the preparation (Table ). It is notable however that these three oils have similar lipophilicities (Table ). On the other hand, homebrewed injectable estradiol preparations used by DIY transfeminine people often employ medium-chain triglyceride (MCT) oil as the oil vehicle. This oil (in the proprietary form of Viscoleo) has notably been found to be much more rapidly absorbed than conventional oils like sesame oil and castor oil in animals. In addition, although based on very limited data, MCT oil has been found to give spikier and shorter-lasting depot injectable curves in humans. As such, injectable estradiol preparations using MCT oil as the vehicle may have differing and less favorable concentration–time curve shapes than pharmaceutical injectable estradiol products. Other excipients, like benzyl alcohol , as well as factors like injection site and volume, have additionally been found to influence pharmacokinetic properties with depot injectables. Excipients besides oil vehicle also vary by formulation (Table ).

Corsi-Rosenthal (CR) Box

A Corsi-Rosenthal Box, more often called a CR box, is a DIY fan powered HEPA filter that you can build for less than $100, often less than $50.

CR boxes were invented during early covid when there was a larger demand for high quality, efficient, and cheap air filtration. Now, even as the public doesn’t care about the raging pandemic anymore, CR boxes remain a vital tool for covid safety. In your DIY lab they are a cheap and effective tool for creating filtered air in your brew space.

This is a perfect alternative to buying an expensive HEPA filtration system.

If you do some investigation, you have a little extra time, and you’re handy (which you should be to be homebrewing), you can build a CR box that utilizes a series of computer fans for a smaller footprint box.

Dry Heat Oven Sterilization

Dry heat sterilization is any type of heat sterilization that does not include both steam and pressure. Typically this looks like heating something in an oven until the heat kills the bacteria by causing “oxidation of cellular constituents and consequently cell death.”1

Dry Heat Sterilization Temperatures1

| Temperature | Time |

|---|---|

| 170°C/338°F | 60 mins |

| 160°C/320°F | 120 mins |

| 150°C/302°F | 150 mins |

Depyrogenation Temperatures

| Temperature | Time |

|---|---|

| 250°C/482°F | 30 mins1 |

| 200°C/392°F | 60 mins2 |

Sterilize vs Depyrogenate

Sterilization is a process that removes or kills all forms of microscopic life3.

Depyrogenation is the removal or inactivation of pyrogens4.

Sterilization and depyrogenation are distinctly different processes that have different parameters and goals. Conveniently, when using dry heat to inactivate pyrogens, sterilization is also achieved. I therefore recommend always depyrogenating all materials in your brew that can withstand the heat. Ultimately this looks like running all glassware through a depyrogenation cycle in order to achieve the dual goals of sterilization and depyrogenation.

Why Depyrogenate Glass When the CSP Can’t be Depyrogenated?

Pyrogens will naturally be part of your brew. Because we cannot heat the CSP up to extreme temperatures, when all is said and done there will be some pyrogens in the final product. Filtration may remove some of the pyrogens, but likely not all. In this scenario, why bother removing some pyrogens when we can’t remove them all?

Pyrogens are “any substance that can cause a fever”4. It is not a single, stray, pyrogen that causes this fever. Instead, it is a critical mass of pyrogens that begin to cause problems for the host4. If we have the option to remove, theoretically, 50% of the pyrogens in a CSP by depyrogenating the glassware, then we should do that.

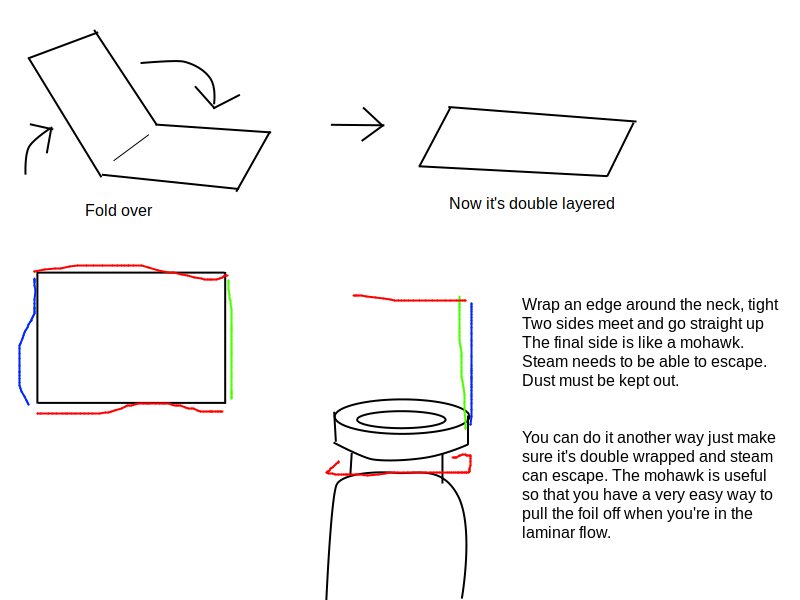

Clean Everything Before Dry Heat Cycle

Before you run the dry heat cycle everything should be properly washed, rinsed, and capped with foil.

Wash: Use a phosphate based detergent such as “Alconox” to achieve lab quality clean. Phosphates are harsh. For small and medium size brews you may choose to use regular dish soap. When reusing glassware, regular dish soap does not remove old oils as well as Alconox. This may result in old oils getting baked onto the glass and essentially ruining the glass as it imparts debris into the brew.

Rinse: Rinse in distilled water. You should use a three stage rinse to ensure all soap is removed. Distilled water is essential to this process as we can’t have tap water or similar leaving minerals behind as the water evaporates out of the glass.

Cap: When glass comes out of the final rinse it should get a foil cap. You want to do this quickly enough that you minimize how long dust has to fall into the glass. Caps should be double layered and have a flute to allow steam to escape, but should be constructed in a way to not allow dust or anything else to fall in. It can be helpful if the caps on vials can be easily removed for a more graceful filling process. Use your head: steam has to escape, dust can’t be allowed in, and they need to be easily removed.

About Temperature Control

This is not baking cookies. When you put the items in the oven, first you have to get the items up to temperature. Once the items are at temperature, only then do you start a timer. You need a laser thermometer to verify the true temperature of your items. If you do not have a laser thermometer you need to get one. If you cannot get one I recommend you leave the items in the oven for at least 30 minutes to get them up to temperature, then after this theoretical 30 minutes of getting up to temp you can start your true timer.

You should use the laser thermometer multiple times during the sterilization/depyrogenation cycle to verify temperatures are holding correctly.

References

View the library page for access to some PDFs.

Footnotes

Glass Vials

Glass vials, responsible for holding your preparation, are important pieces of the equation.

Pre-sterilized

You’ll find that on many websites, including amazon and ebay, you can purchase pre-sterilized vials. This is a practice that I strongly recommend against. We don’t know anything about what these vials underwent before or during their sterilization process. We don’t know if they’re even actually sterile. Maybe they are technically sterile but weren’t washed properly, and so they have dust inside of them.

Pre-sterilized vials offer far too many uncontrollable variables. Please avoid these.

Pre-sterilized for the small guide

If you’re following my small guide, how to make one or two vials at a time, then I’d consider pre-sterilized vials less dangerous. This is for a couple reasons. 1) if something is wrong with the vials it’s only effecting one person, you, 2) you likely don’t have the resources or the equipment to sterilize your own vials, 3) your standards don’t have to be as high when you’re producing for just yourself.

If you want to +1 your setup though, this is definitely the thing to upgrade.

What size vials?

| 3mL vial | 5mL vial | 10mL vial | |

|---|---|---|---|

| 5mg/week & 20mg/mL concentration | 12 weeks | 20 weeks | 40 weeks |

| 5mg/week & 40mg/mL concentration | 24 weeks | 40 weeks | 80 weeks |

| 50mg/week & 200mg/mL concentration | 12 weeks | 20 weeks | 40 weeks |

If you stick with a 3mL vial, and the 20mg/mL concentration for E or the 200mg/mL concentration for T, then you’re left with a vial that will last about 12 weeks. This is a stark difference to most homebrewers who are selling vials that last 80 weeks.

Some folks who are homeless, and who have steady access to supply of fresh vials, will benefit from vials that last much less than this, anywhere from 1-4 weeks. This is due to them having a harder time keeping things clean and the cops messing with their possessions.

The FDA recommends multi-use vials expire after just 28 days, or 4 weeks1. This is unless the manufacturer can prove that the bacteriostatic agent (benzyl alcohol in our case) can preserve their preparation for longer than this time. Since being able to prove this is out of scope for home brewing, I tend to stay closer to the FDA’s guidance than to what is popular in the community.

Washing Vials

Vials need to be washed prior to use. This is to remove any debris or grime from the inside of the vial before sterilization.

Wash your vials in a phosphate detergent such as alconox. Use an appropriately sized bottle brush to clean the insides.

Rinse all vials in distilled water, I prefer a three stage rinse, then loosely cap with aluminum foil hats before their dry heat sterilization cycle. You should cap them before there’s a chance for dust to fall into the vial while the opening is exposed to the air. It should be capped in such a way as to allow steam from the distilled water to escape while not letting anything fall into the vial.

Sterilizing Vials

Vials can be dry heat sterilized in the oven, which can allow for them to be depyrogentated as well.

Depyrogenation temps2

| Temperature | Hold Time |

|---|---|

| 250°C / 482°F | 30 mins |

| 200°C / 392°F | 60 mins |

Reminder that this is how long you need to hold the item at the given temperature for, not how long you need to put it in the oven for. You should use an infrared thermometer to check to make sure your glassware is up to temp.

References

View the library page for access to some PDFs.

Footnotes

Guide Summary

Write yourself a full summary of the procedure before you do it. You’ll want a quick reference that you full own and understand on the day of your brew so that you’re not stumbling around reading the website to figure out what’s next.

Here’s an example copied from HRT Cat.

Example

Do not use this, make your own. There may be errors in this.

- Clear work area

- Sweep and mop

- Hang plastic sheets

- Install and turn on HEPA air purifier

- Sanitize work surface

- Clean floor once more

- Begin wearing shoe covers and garbs in clean room

- Preheat oven to 250°C

- Wash, rinse, and wrap items for depyrogenation

- Put in oven once pre-heated, set timer for 2 hours

- Prepare autoclave with distilled water

- Wash, rinse, and wrap items for sterilization

- Autoclave for 1 hour.

- Wipe down everything else with IPA

- Setup laminar flow hood, leave on

- Remove items from oven and autoclave, stage in clean room

- Inside flow hood, mix in beaker:

- ____mL MCT oil

- ____mL Benzyl Alcohol

- ____mL Benzyl Benzoate

- ____mg Estradiol Enanthate

- Filter into closed 100mL vials

- Dispense into vial, place stopper immediately. Repeat.

- Cap.

- Bubble point test

- Listed bubble point: ____psi

- Today’s air pressure: ____psi

- Starting air volume: ____mL

- Actual bubble point volume: ____mL

- Actual bubble point (calculator ): ____psi

- Full visual inspection

- Make a record

- Label vials

Hormone Esters

An ester is a slight variation on the chemical compound making up the hormone. These cause the hormones to have slightly different properties and half-lives, but are “considered to be bioidentical”1

Recommended Esters

Estradiol

For estradiol use Estradiol Enanthate (EEn). It has a slightly higher half life in the body than Estradiol Cypionate (EC), and a substantially higher half-life than Estradiol Valerate (EV)2. EEn is well suited to be injected every seven days.

Estradiol Undecylate (EU) has a much longer half life in the body than EEn, and can sometimes be preferable to some folks, as many people only inject it every other week. However, this is not a normal ester for DIY, and so most information out there doesn’t apply to EU. This makes EU a poor choice for people who need a weekly routine or for mutual aid orgs who can’t do a lot of education. EU is more ideal for trans feminine people who are heavy into DIY self-education and can confidentially manage their own meds.

Testosterone

Reminder that testosterone is a controlled substance in the United States and many other jurisdictions. This information is intended only for use in locations where testosterone is fully legal.

While both Testosterone Cypionate (TC) and Testosterone Enanthate (TEn) have good half lives in the body, TEn has a melting point that is so low it can convert back and forth between a solid and a liquid during shipping. This makes TC a more obvious choice so you don’t have to deal with this.

References

View the library page for access to some PDFs.

Footnotes

Instant Pot Sterilization

An Instant Pot is good for sterilization in what we call an “Emergency Field Medicine” type situation. This is not an autoclave. I think it’s fair to consider DIY production an “emergency” and so I support its use. Please upgrade to a gravity autoclave if you’re able.

“Only the Instant Pot brand pressure cooker was able to inactivate G. stearothermophilus endospores, which indicated that it would be the most appropriate choice for a laboratory pressure cooker.”1

How To

Assuming your Instant Pot reaches 115-118°C at 10.2-11.6 psi or greater:

Run your sterilization cycle for at least 150 minutes.

This is true of the IP-DUO80 model2, and a few others they make. They may make other models with different ratings, so check your manual. Greater ratings are encouraged, though lesser ratings are prohibited.

Instant Pot Max Pressure Mode

Some instant pots have a “max pressure” mode, which may or may not get up to 15psi. What’s important to note is that instant pots do not achieve stable pressure or temperature. They phase in and out of various pressures, with their max rated pressure/temperature. You can not use an instant pot at “max” pressure as if it is a standard autoclave. It is not an autoclave.

I highly recommend that if you’re using max pressure mode that you stick with the research that is linked on this page, and still use the instant pot for at least 150 minutes. There is no research that supports a lesser time.

Don’t follow Instant Pot’s Sterilization Program

That program is designed for stuff like canning and cleaning. It was not designed to make injectables with.

Consider Upgrading

An upgrade may be within your price range. Look into stove top autoclaves. They leave less moisture behind and we can be more confident that they sterilized our items.

References

Page based on work from HRT Cat

View the library page for access to some PDFs.

Footnotes

Laminar Flow Hood

Working in a laminar flow hood is an entire skill. You must handle things and move your hands in very particular ways. It is beyond the scope of this guide to be able to teach you this skill.

I highly recommend you invest a significant amount of time learning how to work in laminar flow through YouTube tutorials. Try to prioritize videos from pharmaceutical technicians, as they often have a higher standard than mycologists.

Long Term Sterility

You should do as much as possible to ensure your vials are sterile during your brew process. But how can you ensure that they stay sterile once you’re no longer brewing and/or they’re no longer in your hands?

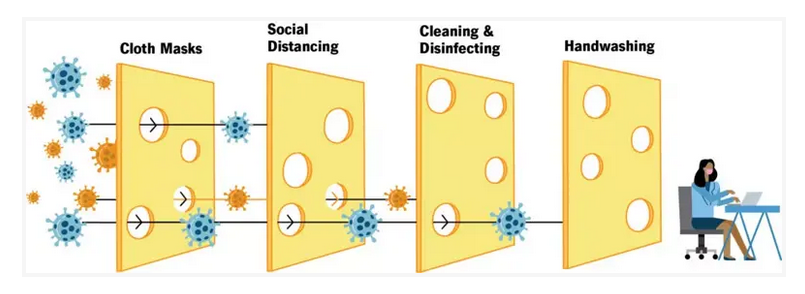

I’d like to present the swiss cheese diagram that became popular during early covid.

This diagram was used to illustrate how a single strategy was not adequate to stop the spread of the pandemic. You can see how each layer of swiss cheese blocks some of the virus particles, but not all of it. According to the diagram, cloth masks helped reduce the spread partially, but we also needed to rely on social distancing, then cleaning/disinfecting, then finally hand washing. If you’re lucky and none of the holes line up then you’ll stop the spread of covid.

While a more modern version of this diagram might have some key updates, my point stands. Sterility does not come from one single place. Sterility comes from lining up all the pieces just right.

One of these pieces, then, is maintaining sterility after a vial is punctured. How can the homebrewer be involved in that process?

Controlling Long Term Sterility by Controlling Vial Size and Concentration

The current norm in the homebrew scene is to make 10mL vials of estradiol at a 40mg/mL concentration. If someone is using an average dose of 5mg, and assuming no loss to dead space, that vial will last someone 80 doses. That’s around 18 months or 560 days.

The United States Pharmacopeia (USP) is handbook published by a 200 year old non-profit who’s sole purpose is to publish information about pharmaceuticals. This book is the standard for all things pharmaceutical. USP chapter 797 recommends that once a multi-use vial is punctured, that it be discarded within 28 days1. The DIY community uses vials for 20 times longer what is recommended by the leading experts in the United States.

These 560 days give vials far too much time to:

- core

- become contaminated

- through coring

- though being drawn from too much

- oxidize

- ingredient breakdown

Instead I recommend making vials targeted to last about 3 months, or, 84 days.

Vial Intended Duration of Use

| USP Recommendation | 28 days |

|---|---|

| DIY Community Norm | 560 days |

| HRT Mom middle ground | 84 days |

Recommended Size and Concentration of Vials

| Testosterone | Estradiol |

|---|---|

| 3mL vial, 200mg/mL | 3mL vial, 20mg/mL |

Dosed at 50mg per week or 5mg per week respectively, these vials will last about 3 months.

If People 100% Need a Year Supply Vial

You can provide them with 4 of these 3mL vials. If someone can store a single vial for a year, the can surely store 4 of them. This a severe matter of safety. We cannot understand the effects of people dipping into the same vials long term like this. We are fortunate that HRT is studied in medical settings to help us understand it’s usage. The application of using the same vial for a year+ is fully outside the scope of medical understanding. We can choose to just play it safe here with almost no drawback.

Please, please do not provide people with vials that are intended to last this long.

Teach Proper Vial Usage

Once the vial is out of your hands, there’s only so much you can do to ensure it’s being used properly. Community members who are using your vials should be doing a few key things:

- Storing at a stable, room temperature

- Storing in the dark

- Always cleaning the stopper with an alcohol swab before drawing

- Using a thin gauge drawing needle (with MCT you can get away with 25g/27g)

- Inspecting for contamination before use

It may be out of your hands to tell each community member who uses your vials this information personally. However you can provide educational material that are intended to go with the vials. This can be a small leaflet, zine, a url on the vial, or even a QR code on the vial. Try your best to get people the info they need to use the vial safely.

References

View the library page for access to some PDFs.

Footnotes

-

USP 797, 2024 edition ↩

Moist Heat Autoclave Sterilization

Please see the pages for

Personal Protective Equipment (PPE)

Wear PPE at all times when brewing. This is to protect you from side-effects of skin contact with the brew or side-effects from any type of inhalation. This is also to protect the brew from coming into contact with things like dead skin cells, your breath, hair, fibers from clothes, bacteria shedding from you/your skin, etc.

What your should wear

- Gloves

- Mask

- Hair net

- Beard net

- Full tyvek suit with cinching wrist wraps

- Shoe covers

This may seem overkill, but I promise it’s not. This is necessary for protecting you and the compounded preparation.

Where to wear

You should have an established “brew area” where you’re always garbed up. Create a marcation line where you do not cross ungarbed/garbed.

Learn more

Check out the page for aseptic technique that has lots of relevant information here linked in some videos.

General tips

- Learn how to properly remove gloves

- No phones, food, drink, etc in the brew area

Recipe calculator

Important Info! How to calculate and mix

After significant experimentation and research it has become clear that you cannot reliably estimate how much carrier oil to add. The displacement of the API, BB, and BA is not consistent enough to make this determination. To hit your target volume you should be working in a graduated beaker, and then

- Add API

- Add BB

- Add carrier oil to be about 10% shy of your target brew volume

You’ll then heat it to not more than 100F/40C and mix. After it’s fully mixed let it fully cool. Fully.

- Add BA (cannot be hot! do not get BA hot!)

- Add carrier oil to target brew volume

What this process does is allow for us to have the exact ratios we’ve calculated for for our API and other inactives. We let the carrier oil get us to the exact volume we need to be at which assures that all our other ingredients are in correct ratio to each other.

Rubber Stoppers

Stoppers are the thing that closes a vial. Often made of butyl rubber, you push a needle through the stopper to draw out your preparation before injecting it. When making vials, a cap is crimped on top of a stopper.

Two important points

-

Silicone stoppers are NOT compatible with benzyl alcohol (BA), an essential component of your homebrew. Benzyl alcohol is studied to be able to pass through, and evaporate out of, silicone. Benzyl alcohol is present in the solution to prevent the proliferation of bacteria, it is not optional. Taking risks surrounding benzyl alcohol is not worth it.

-

Butyl rubber stoppers are NOT compatible with oven sterilization. You cannot sterilize them in the oven at all, either before you assemble the vials or as part of a complete, sealed vial. Butyl rubber will begin to off-gas and therefore leech harmful chemicals into your preparation. Butyl rubber must be sterilized in the autoclave.

Off Gassing

In my own experiments, I have discovered that at any valid sterilization temperature, the butyl rubber stoppers begin to breakdown in the heat. This one time it released a horrific off-gassing into my space, where everything smelled of burning rubber. This was at the lowest, temperature, 140°C/284°F. Now, imagine that off-gassing is happening, but the rubber stoppers are fully capped and enclosed. That gas is leaving the stopper and coming into contact with the HRT. It’s impossible to know if leeching takes place. I’m certainly not going to inject something that underwent that process. I also suspect the butyl rubber that’s been overheated cores more easily, but I have no data to prove this.

Butyl rubber cannot be replaced with silicone due to the documented ability for benzyl alcohol to pass through and evaporate out of silicone tubing.1

Notes and Sources

View the library page for access to some PDFs.

- BB + Silicone are a bad match

- BA evaporates through silicone barriers

- Silicone absorbs MCT oil (no sources cited)

Footnotes

Sterility Assurance Testing

This page is just notes. If you desire to perform sterility assurance testing you will likely need to perform additional research. Take a look at the references on the bottom of the page.

Procedural Information

Make FTM tubes

Using 3mL vials and 15mL test tubes.

- Mix the FTM broth with distilled water as per the package instructions

- Add polysorbate 80 at a concentration of 40mL/L

- Add 13.5mL to test tubes

- Autoclave test tubes

Add the CSP

- Choose the number of vials to test.

- Under laminar flow add 1.5mL from each vial to a tube

- Seal.

Incubate

You will likely be incubating 4-10 tubes.

Tubes should be incubated at 30-35°C (86-95°F) for 14 days1.

Observe

Cloudy tubes mean contam?

Sterility Assurance Testing Notes Below

We can test the sterility of our finished product if we have some special supplies and tools. For this tek we’re working with two different growth mediums as recommended by USP 71 and the book “Compounding Sterile Preparations.” These are Tryptic Soy Agar (TSA) and Fluid Thioglycollate Medium (FTM)2.

Notes Below

What tube size should we be using?

Tube contains:

- 1.5-5mL of CSP (50% of vial)

- 13.5-45mL of FTM (with polysorbate 80)

the volume of the product is not more than 10% of the volume of the medium

For testing 3mL vials, we need 15mL tubes.

USP 71

How many vials to test?

| Total vials produced | Vials to test |

|---|---|

| Less than 100 | 10% or 4 vials, whichever is more |

| 100-500 | 10 vials |

| 500+ | 2% or 20 vials, whichever is less |

From USP 71

How to neutralize the BA?

If the product to be examined has antimicrobial activity, carry out the test after neutralizing this with a suitable neutralizing substance or by dilution in a sufficient quantity of culture medium1

BA is neutralized by Polysorbate 80 at a concentration of 40mL/L3

Testing Oily Liquids?

Use media to which have been added a suitable emulsifying agent at a concentration shown to be appropriate in the Method Suitability Test, for example polysorbate 80 at a concentration of 10 g per L.1

Is TSA even needed aside from fingertip tests? Can just stick with FTM solely?

How much P80 to add?

- 40mL per L for neutralizing BA

- 10g per L for emulsifying

Which is greater? P80 is 1.06g/mL

10g is 9.43mL.

Verifying Your Test is Suitable

After transferring the contents of the container or containers to be tested… to the culture medium, add an inoculum of a small number of viable microorganisms (not more than 100 cfu) to the medium.

In both cases use the same microorganisms as those described above under Growth Promotion Test of Aerobes, Anaerobes, and Fungi. Perform a growth promotion test as a positive control. Incubate all the containers containing medium for not more than 5 days.

If clearly visible growth of microorganisms is obtained after the incubation, visually comparable to that in the control vessel without product, either the product possesses no antimicrobial activity under the conditions of the test or such activity has been satisfactorily eliminated. The test for sterility may then be carried out without further modification.

If clearly visible growth is not obtained in the presence of the product to be tested, visually comparable to that in the control vessels without product, the product possesses antimicrobial activity that has not been satisfactorily eliminated under the conditions of the test. Modify the conditions in order to eliminate the antimicrobial activity, and repeat the Method Suitability Test.

This method suitability is performed (a) when the test for sterility has to be carried out on a new product; and (b) whenever there is a change in the experimental conditions of the test. The method suitability may be performed simultaneously with the Test for Sterility of the Product to be Examined.1

Since we don’t have access to strains of bacteria aside from what we can just pickup in the kitchen sink, we need to adapt this test for home use.

Supplies

- Laminar flow hood

- Incubator

- Autoclave

- Media bottles

- Tryptic Soy Agar plates

- Fluid Thioglycollate Medium tubes

- Polysorbate 80 as an emulsifier

You can potentially substitute your laminar flow hood here for a still air box, but your results won’t be as consistent or trustworthy.

How to make TSA plates

You can make TSA with neutralizers if you’d like to perform fingertip testing4, a way of verifying how solid your personal aseptic technique is. Do not use neutralizers otherwise.

- Sterilize empty agar plates

- Mix the TSA powder with distilled water according to the TSA package.

- Autoclave in a media bottle

- When TSA cools to a handling temperature, but before it solidifies, pour the liquid TSA into agar plates under a laminar flow hood and immediately cover.

- You can optionally add a small piece of tape to keep them shut

- Let cool fully before use

If you’re using this right away, make sure to set a couple aside to ensure that they were sterilized correctly and aren’t growing bacteria you didn’t mean to introduce.

Using TSA plates

TSA plates should be incubated at 20-35°C (68-95°F) for 14 days5.

Using FTM tubes

Heat in a water bath prior to use.1

FTM tubes should be incubated at 30-35°C (86-95°F) for 14 days1.

How much product to test

The minimum volume of each CSP [compounded sterile preparation] to be tested is dependent on the volume of the final product. If the product is <1 mL, the entire volume must be tested. If 1-40 mL, then half the total volume is tested. If 40-100 mL, then 20 mL is tested. If the volume is >100 mL, then 10% of the volume is tested (but at least 20 mL).6

If the individual containers (for end-user use) have between 1-40mL in them (like what we’re doing here on HRT Mom), then sterility testing is done on 50% of the volume of the containers7

“the product is not more than 10% of the volume of the medium”7

References

Some information on this page comes from HRT Cat.

View the library page for access to some PDFs.

Footnotes

Sterilization Temperatures

In depth information lives on the pages for the individual methods:

Dry Heat Sterilization Temperatures1

| Temperature | Time |

|---|---|

| 170°C/338°F | 60 mins |

| 160°C/320°F | 120 mins |

| 150°C/302°F | 150 mins |

Dry Heat Depyrogenation Temperatures

| Temperature | Time |

|---|---|

| 250°C/482°F | 30 mins1 |

| 200°C/392°F | 60 mins2 |

Moist Heat Autoclave Sterilization Parameters3

| Temperature | 121°C |

| Pressure | 15 psi |

| Time | 20-60 minutes* |

*You’re supposed to choose a time that you can verify is correctly sterilizing your product. Since that’s typically out of scope for DIY operations, you may choose to sterilize for the maximum recommended time. The CDC recommends 30 minutes4.

Instant Pot Sterilization Parameters5

| Setting | Pressure cook high or max |

| Time | 150 minutes |

References

View the library page for access to some PDFs.

Footnotes

-

USP 797 section 10.3, 2024 edition ↩

-

Assessment and verification of commercially available pressure cookers for laboratory sterilization ↩

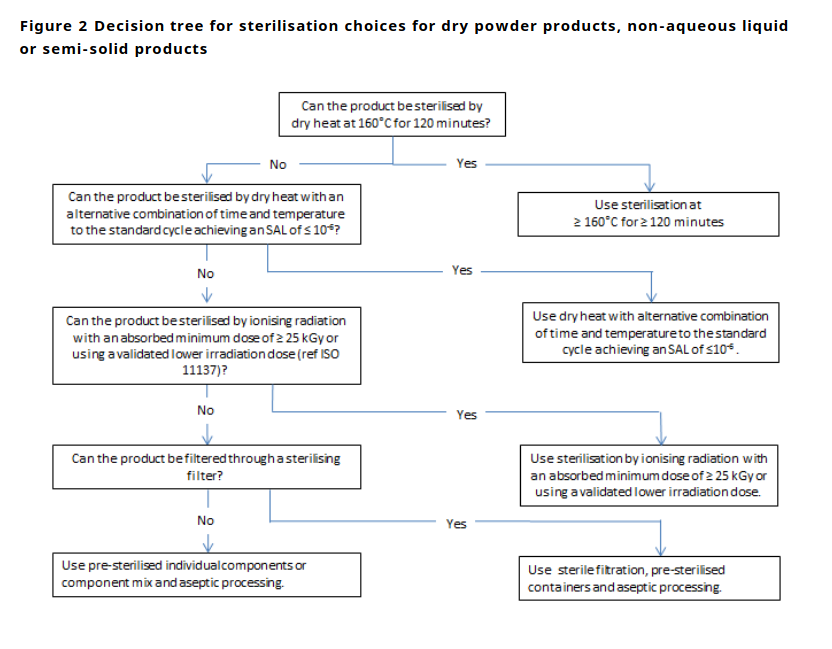

Sterilization Theory

Sterilization requires a set of knowledge specifically catered to the compounded product that you’re working with. Sterilization is not so cut and dry that every solution works for everything.

Our CSP (compounded sterile preparation):

-

Is a non-aqueous liquid (it’s not water, it’s oil)

-

Starts with non-sterile components

-

Cannot endure dry heat sterilization (due to the benzyl alcohol1 and rubber stoppers2)

-

Cannot be sterilized by steam (it’s non-aqueous and due to the benzyl alcohol1)

- USP 797 says: “Steam sterilization is not an option… if there is insufficient moisture to sterilize the CSP within the final, sealed, container closure system”3.

-

Can be filtered

Filtration and Aseptic Technique

For the above reasons we are going to need to sterilize our compounded preparation using solely filtration and aseptic technique.

Why doesn’t dry heat sterilization work? (Ovens)

Dry heat sterilization generally involves heating something up to 160°C for at least 120 minutes. Any time there is no steam and pressure contact being made with the subject of the sterilization, it’s considered “dry heat.” A glass wall between the steam and the contents of a vial make it’s autoclaving still technically “dry heat,” as the steam does not make contact with the contents of the vial.

You cannot dry heat sterilize finished vials.

Reason 1: benzyl alcohol, the vital preservative in the vial, can break down, release a toxic byproduct, and evaporate with heat (more info)

Reason 2: butyl rubber stoppers begin to break down and off-gas (more info)

Reason 3: benzyl benzoate may break down with heat

Reason 4: while anecdotally the hormone may remain stable with high heat, there is no scientific evidence to support this.

Why doesn’t steam sterilization (autoclaving) work?

Reason 1: same as reason 1 above, benzyl alcohol can’t handle the heat. (more info)

Reason 2: for steam sterilization to be effective, the product that is meant to be sterilized must come into contact with steam, not the container or vial, but the product itself5,6,7.

Reason 2a: This isn’t true IF the contents of the vial are water based, that way the contents can create their own steam and pressure system as they heat up. However, our CSP is oil based, so this won’t work.

USP 797 says: “Steam sterilization is not an option… if there is insufficient moisture to sterilize the CSP within the final, sealed, container closure system”3.

”I think you’re wrong, it’s about the energy transferred to the glass vial by the steam”

No. It’s true that the energy transferred to the glass will happen more quickly in the steam than in dry heat, but that energy transfer still maxes out at 121C, far below what’s needed when there’s no steam/pressure making contact with the microbes. Without the steam making direct contact to the microbes in question, this is just heating something up really fast, the steam isn’t doing anything else.

Filtration & Aseptic Technique

Filtration and aseptic technique is the only viable combination that can get us safely sterilized vials. Be wary of anyone who is teaching how to homebrew HRT and does not understand these concepts fully and clearly. There is no benchmark that someone has to hit to be able to write about and teach this stuff online. There are lots of highly unqualified people out there giving bad advice. 99% of advice I find online about how to homebrew is incorrect.

References

Some sources pulled from HRT Cat

View the library page for access to some PDFs.

Footnotes

-

More research about benzyl alcohol here ↩ ↩2

-

More research about rubber stopper here ↩

-

Guideline on the sterilisation of the medicinal product, active substance, exicpient and primary container ↩

-

Compounding Sterile Preparations, pg 254 ↩

-

Steam Sterilization vs. Dry Heat Sterilization For Medical Devices & Products ↩

-

Steam Sterilization Principles & Common Mistakes Using Autoclaves ↩

Still Air Box

A still air box is basically just an upside-down large clear tupperware container with two arm holes cut in it. The idea is that if you clean the box really well, set it up, put all your stuff in it, and then just let it sit, that the majority of bacteria that’s floating around the air inside the box will settle to the floor of the box. Then, when you stick your arms in the box to work, you’re working in slightly cleaner air than you would be outside of the box.

Look up some YouTube tutorials on how to build a box and how to use it. The mycology community is your friend with this one.

Do not build a box that has gloves taped to the inside of it. While at first it seems like this would keep the box from being exposed to new air when you insert your arms, the reality is that because the box isn’t sterile on the inside to begin with, that the gloves end up facilitating a bunch of air currents inside the box, and stirring around a lot more bacteria than it would otherwise.

The still air box can be used for the small guide (optional) or the medium guide (required). It cannot be used for the large guide.

Syringe Filters

Use 0.22μm sterile PTFE syringe filters

You can potentially replace the PTFE material with Nylon, however there appears to be less data indicating safety, and this should require more research.

PTFE is safe with oil, benzyl alcohol, and benzyl benzoate1 2.

Details (for sterilization)

- Pore Size: 0.22μm (this size is required for sterilization)

- Sterility: Use pre-packaged, sterile filters.

- Size: if you’re filtering 1-10mL, use a 13mm filter. 10-100mL use a 25mm filter3. 100m-250mL use a 33mm filter4. Larger is generally easier to push though.

- Filter material: Polytetrafluoroethylene (PTFE). Nylon filters may work, but require more research to verify.

- Hydrophobic or Hydrophilic: Inconsequential for an oil-based solution.

Details (for pre-filtration)

- Pore Size: 0.45μm

- Sterility: not required

- Size: if you’re filtering 1-10mL, use a 13mm filter. 10-100mL use a 25mm filter3. 100m-250mL use a 33mm filter4. Larger is generally easier to push though.

- Filter material: Polytetrafluoroethylene (PTFE). Nylon filters may work, but require more research to verify.

- Hydrophobic or Hydrophilic: Inconsequential for an oil-based solution.

Don’t use PVDF of PAS

Benzyl benzoate, an ingredient in the brew, can cause PVDF filters to dissolve. This could have potential side effects such as filters breaking or PVDF leeching into the filtered solution. There is minimal data to support whether PVDF is safe, so in this case it’s best to air on the side of caution5.

Bubble Point

Many, but not all, filters will list a bubble point or “max burst pressure”. Check or confirm this bubble point by testing the bubble point of your filters with a sample of your solution. Bubble points can change when the filters are pre-wetted with different solutions, so always check with your actual brew.

Read more about bubble point testing here.

Cheap Filters vs High Quality Filters

There are many filters available in small 10 packs on websites like Amazon. While these filters are economical they are of substantially lower quality.

| Amazon/eBay/etc Filters | High Quality Filters | |

|---|---|---|

| Cost per | $1.30 each | $2.00 each |

| Pack Size | 10 | 100 |

| Total Cost | $13 | $200 |

| Bubble Point | Variable 30-45psi | Consistent 50psi |

| Filter Speed | 80-120 seconds per 1mL | 15-30 seconds per 1mL |

If you can afford the upfront cost of higher quality filters they make a massive difference. This makes less sense for those following the small or medium guides.

Opinion: I have a theory about these filters which I can’t prove without a microscope or something. Lower Quality (LQ) filters likely have inconsistent pore sizes on the filter surface + less stable filter surface, while Higher Quality (HQ) filters likely have an extremely consistent pores on the filter surface with strong stability. I believe this for a few reasons. First, from a purely economical standpoint, an Amazon seller has less incentive to make a high quality product compared to a company who’s whole business is manufacturing filters. Second is the variable bubble point. On an LQ filter, I might get a bubble point of 45psi, and then push 20mL of product though it, then suddenly start getting 30psi bubble point. To me this indicates that it degraded while it was being used. HQ filters on the other hand will always come back with a consistent 50psi when I’m using them in a normal way. Finally, during the bubble point test itself, LQ filters put off a stream of bubbles about 0.5mm in size, where as HQ filters are putting out something more akin to foam, which is bubbles more on the scale of 0.05mm each. Why would LQ filters release air bubbles almost 10x the size of HQ filters? To me this points back to the quality of the filter itself, the HQ filters may have more consistent pore sizes and may be letting smaller pockets of air through at once.

Compatibility Charts

https://www.restek.com/globalassets/pdfs/literature/gnts2123-unv.pdf

https://scientificfilters.com/membrane-Filter-chemical-compatibility-chart/

https://www.ddbiolab.com/data/pdf_guides/en/Tableau_de_compatibilite_chimique_Whatman.pdf

https://www.astisensor.com/KYNAR_PVDF_Chemical_Compatibility_Resistance_Chart.pdf

https://www.calpaclab.com/teflon-ptfe-compatibility/

https://www.growinglabs.com/pages/syringe-filter-solvent-compatibility

References

Page based on work from HRT Cat

View the library page for access to some PDFs.

Footnotes

Brew HRT Topicals

Brewing topicals isn’t my specialty, but I have some resources I can point you towards:

Resources

I do not endorse the following, just linking them. Do your own research to determine if you’re getting good info or not.

- r/estrogel - Discussion board for getting help brewing topicals.

- r/estrogel’s Wiki - dosing, recipes, sourcing, and more

- Boobs Not Bombs - a large scale guide for brewing for you and your community

Small Scale Guide: Preliminaries

Brew Estradiol or Testosterone

Unlicensed production of testosterone may be illegal in your region.

Warning

This guide creates injectables. This injectable is designed to go into your body, bypassing the wonderful filtration system of your digestive organs. Injectable preparations are inherently more dangerous than topicals or orals. Do not skip steps. Do not skimp on prices. You want to do this, so do it right, the first time.

Please contemplate if you’re capable of doing this process correctly before beginning.

Scale

This guide is designed to create roughly 10mL of your target preparation.

It can do more but it’s stretching the capabilities of the equipment and you start encountering more safety issues and considerations. Consider upgrading to the medium guide if you need more than a couple small vials for personal use.

Bare-Bones Guide

This guide is completely bare-bones. I’ve stripped out everything that’s not completely essential. This is because this is a harm-reduction based guide that’s meant to make your personal homebrewing as easy and accessible as possible while still staying safe.

You can up your game by reading the medium scale guide and taking tools and methodologies from there.

Other Guides

I don’t recommend any other guides for this procedure. There’s a lot of bad info out there.

DIY vials are a science, not an art. While there will always be a difference in opinion, I know we can collectively step up our game. Just because people “aren’t getting hurt” by the current state of DIY doesn’t mean it’s adequate. I believe that in some circumstances there could be longterm health consequences to poor technique.

Small Guide Contents

- Defining and gathering supplies

- Building a work area

- Preparing materials

- Mixing preparation

- Filtering into small vials you’ll later inject from

- Using bubble point tests to ensure filter integrity

- Visual exam

Pre-Brew Education

Please read up before beginning this process

- Read this whole guide start to finish

- Make a list of how this guide is different from what you’ve done in the past

- Explore the items in “Topics” area of the sidebar to improve your knowledge

Science-Mind

When you homebrew you’re doing something that is highly regulated and whose secrets are highly guarded. It’s also pretty dangerous to cook something in your kitchen and then to inject it into your own body. You’ll be best served if you adopt a science mindset as you move forward. Ask as many questions as you can about why things are they way they are. Ask if things are safe or not. Ask why we know if they’re safe or not. Keep this up and never stop.

You should be thrilled to learn that there’s a better way to do something. Treat every failure as a success because your set of knowledge just got broader. Be cautious of people with homebrew knowledge who are highly defensive and who have no data to back up why what they do is “safe.”

Accidental skin contact

Be aware that gloves should be worn while following this guide. All people can have their hormone profile interfered with if they make accidental skin contact with what they’re brewing. If you are a person who has hormone cycles, or a person who is on testosterone to suppress those cycles, you may notice that accidental skin contact is detrimental to that cycle.

You will come into contact with this preparation, and you need to have PPE protecting you.

A lot can go wrong here, I’ve seen it first hand. Protect yourself.

Create a guide summary

Preparing for the day of your brew, you should have a personal summary of this guide written out so you don’t have to refer to a website constantly.

Notes of safety

Some safety decisions have to be made.

Most brew guides will direct you to make 10mL vials at a high concentration such as 40mg/mL. While this is super convenient for making a single vial last you around 80 weeks, there are some large safety concerns with this.

The FDA recommends that once you puncture a vial, that you discard it after a mere 28 days. A deviation of this size is too large to ignore. While we know that those in the DIY community seem to have perfectly fine results from doing this, we don’t know if it’s actually safe or not. Even with the best technique, over time you will be degrading the stopper and introducing bacteria into the vial.

80 weeks feels excessive to me for this. If you, instead, make a 5ml vial of 20mg/mL concentration, you’re looking at a vial that lasts you around 20 weeks. While 20 weeks is still way over the 28 day threshold thats recommended, it’s at least a bit saner of a stretch.

I prefer vials that are 3mL and 20mg/mL concentration, and thus last around 12 weeks.

Figure out what makes sense for you.

Decide on your recipe

Head over the recipe calculator and calculate your recipe. For this specific methodology I’d suggest you make 1 or 2 5mL vials of 20mg/mL Estradiol or 200mg/mL Testosterone. At average dosing, a 5mL vial will last you about 5 months.

Brew at least an extra 5mL more than you plan on dispensing into vials to account for loss to the filter etc.

Small Guide: Supplies

Active Pharmecutical Ingredient (API)

Other Excipients

Vials

- Pre-sterilized 3/5/10mL Vials (Please get these from a reputable vendor, not amazon/ebay).

Tools

- Oven

- Work surface

- Milligram scale

- Glass stirring rod (use a metal spoon or butter knife in a pinch)

- Baking dish

- 50mL graduated beaker (optional but very helpful)

OR

- Pyrex beakers of appropriate size for mixing. Any glass that can be oven sterilized works too (many drinking glasses will break in the oven, but you might have better luck with a glass jar for pickling)

Disposables

- 18g sterile luer lock needles (optional, used for drawing ingredients)

- 27g sterile luer lock needles (for filtering into sterile vial)

- 3mL sterile luer lock syringes

- 10mL sterile luer lock syringes

- Sterile 0.22μm PTFE syringe filters

- Isopropyl alcohol 70% (IPA) (buy exactly 70%)

- Disinfecting hand soap

- Paper towels

- Aluminum foil

Personal Protective Equipment (PPE)

- Latex/nitrile gloves

Small Guide: Supplies

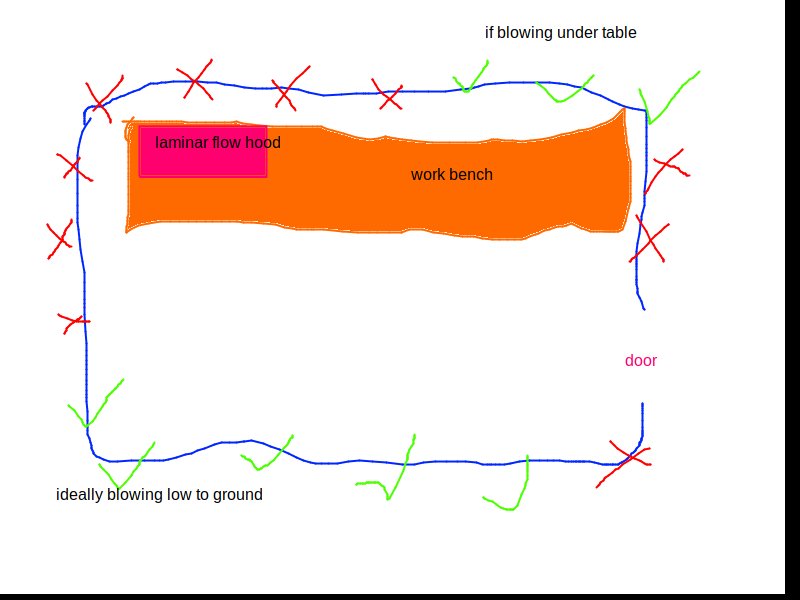

Identifying and Creating a Work Area

Your work area should be on a table or counter top, ideally not wood, that is away from carpet and pets.

If you can’t get away from carpet, then you need to vacuum the day before brewing very, very well.

If you only have a wood work surface, put down some plastic sheeting or something to work on top of to protect the wood from the brew.

When you’re working you should not have any fans running unless they are part of a HEPA filtration system.

Don’t brew next to an open window, or next to a window with the blinds open (don’t want the neighbors to see what you’re doing).

Fully clear off the work surface and clean it really well. Only add the items back to the work surface that you’re going to need for your brew. Everything else can stay elsewhere for now.

Wash and Sterilize Tools and Vials

Your mixing glass and your glass stir rod are going to come into contact with the brew. Let’s sterilize them first so that we can eliminate bacteria in the mix.

- Wash both items very well with dish soap

- Rinse with clean water or distilled

- No need to dry

- Cover the opening of the mixing glass/beaker/jar with aluminum foil, giving it a little hat. Make sure to not cramp down too tight with the foil as we want the steam to be able to escape

- Similarly, wrap the stir rod in foil, accounting for the fact that you want moisture to be able to escape

Home ovens kick around a lot of oil when they get turned on. The foil is partially to prevent any dirt/oil/particles from your oven from getting on your brew supplies.

Pre-heat your oven to as high as it goes, but no higher than 500°F/260°C.

Once it’s preheated, place the baking sheet in the oven and cook for the following times according to the temperature you’re oven is able to achieve:

| Temperature | Time |

|---|---|

| 500°F/260°C | 60 mins |

| 400°F/200°C | 90 mins |

Remove from the oven and let cool to room temperature. Don’t unwrap the items.

Small Guide: Mix

Recipe

Go to the recipe calculator page to determine what your recipe is.

The calculator will not tell you how much oil to add. This is intentional, however it may cause problems for your small scale brew if you don’t have a scientific beaker with measurements on the side. If you do have a small graduated beaker, use that and follow the mixing guide on the recipe calculator page. Otherwise read below.

Mix Without a Graduated Beaker

You can work in a still air box if possible, but it’s not strictly required for the small guide.

Instead of using a graduated beaker, add the API and BB to your mixing container. Whatever volume of BB you added, add the same volume of your oil. Write down how much you’re adding in order to keep track of what’s what. Now mix it up real good until the API is dissolved. If the API is refusing to dissolve fully after 5 minutes of stirring, go ahead and add a little more oil (keeping track of how much you’re adding).

Now you can draw your whole preparation up into a syringe or two. Use these to measure what the total volume of your preparation is. When you used the calculator you said what volume you are trying to brew, so this is the number your want to hit as a total volume. Add your benzyl alcohol, and then add the amount of oil to your mixing container that is needed to achieve this TOTAL volume.

Example:

I’m brewing 25mL of 20mg/mL Estradiol at a theorized 100% purity.

The recipe calculator tells me to use:

- 0.5g Estradiol Enanthate

- 5mL Benzyl Benzoate

- 0.5mL Benzyl Alcohol

- Carrier oil fill to 25mL

So I add 0.5g of estradiol enanthate, 5mL of benzyl benzoate, and 5mL of oil to my mixing glass.

I mix this for five minutes. The estradiol isn’t fully dissolved, so I add another 5mL of oil. The estradiol dissolves fully.

I suck up the preparation with two different 10mL syringes. I see that the total volume of the preparation is 19.5mL.

I add 0.5mL of benzyl alcohol to the mixing glass.

This brings the total volume up to 20mL. My target volume was 25mL. This means I need to add an additional 5mL of oil to the mixing glass.

I add all the preparation from my syringes back to the mixing glass and stir well. Mixing complete.

Cover the Preparation

As soon as the preparation is properly mixed cover it with aluminum foil to prevent any dust or bacteria from falling in.

”Why is the Mixing So Complicated?”

The mixing is complicated because it’s difficult to determine exactly how much volume your API displaces. Using basic density measurements for the API proves to be ineffective with this. This problem is sidestepped using the above method.

Filter & Dispense

Preparing

In your work area you have

- Mixed preparation

- 10mL syringes

- 2 27g needles (wrapped)

- a 18g needle (wrapped) (27g okay)

- a sterile 0.22 PTFE syringe filter

- Pre-sterilized and sealed vials (3mL, 5mL, or 10mL)

- Alcohol swabs

- Gloves (on your hands)

Filter & Dispense